PSI / Pikotek

Link-Seal® Modular Seals

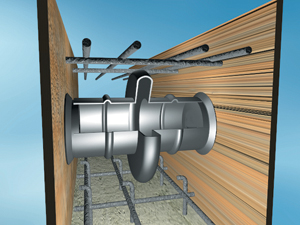

Link-Seal® modular seals are considered to be the premier method for permanently sealing pipes of any size

passing through walls, floors and ceilings. In fact, any cylindrical object may be quickly, easily and

permanently sealed, as they pass through barriers, by the patented Link-Seal® modular seal design.

Ductile iron, concrete, metal as well as plastic pipes may be hydrostatically sealed within walls to hold

up to 20 psig (40 feet of static head). Electrical or telecommunications cable may be sealed within

conduit as they enter vaults or manholes. The annular space between carrier pipes passing through casings

may be sealed against the entry of water, soil or backfill material.

Ductile iron, concrete, metal as well as plastic pipes may be hydrostatically sealed within walls to hold

up to 20 psig (40 feet of static head). Electrical or telecommunications cable may be sealed within

conduit as they enter vaults or manholes. The annular space between carrier pipes passing through casings

may be sealed against the entry of water, soil or backfill material.

With a wide variety of hardware/elastomer combinations, Link-Seal modular seals are easily configured

to achieve the best possible match for service conditions encountered. High temperature seals, fire seals

(Factory Mutual Approved) and oil resistant seals may be ordered to meet special or unique service

applications. For the system approach, metal or non-conductive Century-Line® sleeves with water stops

may be ordered with Link-Seal modular seals to ensure correct positioning and a water tight seal of the

installation within poured concrete walls.

Link-Seal modular seals are also available for a wide variety of special applications, temperature

extremes and exotic chemical combinations.

Saves time and money...

Link-Seal modular seals install in up to 75% less time compared to lead-oakum

joints, hand fitted flashings, mastics or casing boots.

Positive hydrostatic seal...

Link-Seal modular seals are rated at 20 psig (40 feet of head), which exceeds the performance requirements of most applications.

Long seal life...

Link-Seal modular seals are designed for use as a permanent seal. Seal elements are specially compounded to

resist aging and attack from ozone, sunlight, water and a wide range of chemicals.

Maximum protection against corrosion...

Standard fasteners have a two-part zinc dichromate and proprietary corrosion inhibiting coating.

Corrosion resistant 316 stainless steel available for maximum corrosion protection.

Certification/Approvals...

Factory Mutual Fire Approvals.

Also a wide variety of approvals from various Federal agencies, associations, code groups, laboratories and organizations.

ISO Quality Assurance...

Link-Seal modular seals are manufactured in an ISO 9001:2000 certified facility.

Configure a Link-Seal modular seal to match your application...

16 sizes, color coded EPDM, Nitrile, & Silicone elastomers may be used with various hardware options to match

performance characteristics with service conditions.

Century-Line® Sleeves

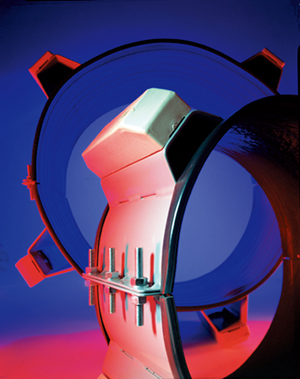

Century-Line® Pipe Penetration Sleeves are used to create circular sleeved holes in concrete poured barriers

including; walls, floors, ceilings, structural supports and tank footings. Molded from non-conductive, high

impact resistant HDPE, Century-Line® sleeves are lightweight and easily installed by one construction worker.

They are available in 16 diameters ranging from 2" to 25" and shipped, from stock, in any desired length.

Century-line® sleeves are engineered to mate with Link-Seal® modular mechanical seals for a lifetime of

leak-proof performance. PSI/Thunderline?Link-Seal® is your one-stop source for everything you need to

effectively seal the annular space between pipes and concrete barriers through which they pass.

Century-line® sleeves are engineered to mate with Link-Seal® modular mechanical seals for a lifetime of

leak-proof performance. PSI/Thunderline?Link-Seal® is your one-stop source for everything you need to

effectively seal the annular space between pipes and concrete barriers through which they pass.

16 sizes - 2" to 25" in diameter - Local stock, drop ship overnight...

In the event of a field or engineering change, sleeves may be cut shorter at the job site using ordinary hand tools.

Standard sleeves are 16" (406mm) in length. Longer length models may also be quickly fabricated as a custom ordered item.

1/8 the weight of steel...

Century-Line® sleeves are light enough for one worker to install without a crane, hoist or helper which

reduces installation time and costs. Century-Line® sleeves are easy to stock and store and far less expensive to ship,

when compared to steel sleeves.

Resists water migration...

The 2” (50.8mm) water stop collar not only anchors the sleeve in position but creates a long tortuous

path against the migration of water around the outside of the sleeve.

Used for shotcrete wall applications...

For shotcrete applications, Century-Line® Sleeves are easily positioned to wall form with threaded rod,

and the end caps protect the sleeve penetration while the wall is formed.Z

Adjusts to wall thickness...

Century-Line® sleeves unique hollow water stop collar acts like an expansion joint, adjusting (up to 1/2” - 12.7mm)

to the thickness of the wall. This compressive force reacts against the forms like a spring, creating a prevailing

tension which maintains proper sleeve location within the form.

Nailer end caps position sleeve precisely in form...

Specially designed end caps provide an ideal method for attaching Century-Line sleeves to the concrete forms.

The end caps assure that the sleeve holds its circular configuration during the pour.

In addition to keeping out wet concrete, they also prevent dirt from entering the sleeve during

backfill operations or the interim construction period.

Tough high density polyethylene (HDPE) construction...

High impact-resistant HDPE also provides excellent resistance to acids, alkalis and other organic solvents.

Ideal for cathodic protection systems, these non-conductive sleeves will neither rust, corrode or degrade.

Low-temperature properties are such that they may be installed under any weather conditions suitable for

pouring concrete. High termperature application limit is 150º F. (66º C.). The sleeve is molded with a

texture on the outside surface to assure a better bond, than most other plastics, to concrete interfaces.

PSI / Pikotek Model "C" Coated Metallic Casing Spacers

An extremely tough and durable heat fused fluid bed thermo set cross-linked polymer coating is

offered on steel casing spacers/isolators 4" and larger, with 8" and 12" band widths. The cold

formed steel casing spacer/isolator band (risers where applicable) and studs for runner mounting

are grit blasted, heated and fusion coated with a cross-linked epoxy polymer formulation,

providing a minimum 0.010 (0.254mm) thick coating over the entire metallic surface. A post cured

cycle strengthens the bond and provides an even more uniform coating.

are grit blasted, heated and fusion coated with a cross-linked epoxy polymer formulation,

providing a minimum 0.010 (0.254mm) thick coating over the entire metallic surface. A post cured

cycle strengthens the bond and provides an even more uniform coating.

Other heat fused formulations are also available for custom orders and applications.

The runners are attached with 3/8" diameter studs, which are fusion welded to the band before it

is powder coated. They are recessed far below the wearing surface of the runner. After the runner

is anchored to the band, the stud counter-bore is filled with specially formulated caulk to assure

a water tight seal for the stud and the locking fastener.

|

Targeted Use - Energy, Water and Filled Casings |

- Low Labor Costs - May Be Installed By One Person

- Glass Reinforced Nylon or Polyester Runners Offer Low Coefficient of Friction = 0.1 to 0.6

- Glass Reinforced Nylon or Polyester Runners Offer 18,000 PSI (1,265kg/cm²) Compressive Strength

- Riser Height May Be Specified For Specific Positioning of Carrier Pipe Within Casing

- Heavy Duty PVC Inner Liner Provides Protection For Pipe and/or Coating

- Offers excellent corrosion resistance

- May be used for long pulls and/or heavy pipe installations

- Designed to last for the life of the piping system

- PVC Liner Provides Back-up Isolation

- Deeply Embossed Flanges Offer Added Strength During Tightening of Flange Bolts

- Eliminates the Need for Blown Sand or Pea Gravel

- Available with 8" or 12" bands

- 10 or 7 gauge risers may be ordered

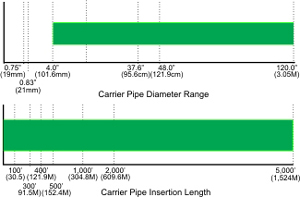

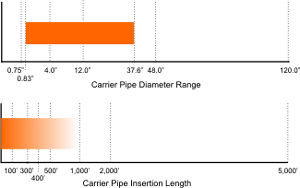

PSI / Pikotek RangerII® Non-Metallic Casing Spacers

The Ranger II® is an all non-metallic casing isolator/spacer system that uses molded

segments to encircle the

carrier pipe. Each segment includes at least one molded-in runner and one slide lock. Customer's may choose

from any one of five different size bands to allow correct sizing for carrier pipe O.D. ranges from 0.83" up to 37.60" in diameter.

segments to encircle the

carrier pipe. Each segment includes at least one molded-in runner and one slide lock. Customer's may choose

from any one of five different size bands to allow correct sizing for carrier pipe O.D. ranges from 0.83" up to 37.60" in diameter.

Once sized, the segments are placed around the carrier pipe and cinched together via non-metallic slide locks.

Installation is quick and easy while only a small inventory of segments may be used to accommodate a large variety

of pipe styles, types and diameters.

|

Targeted Use - Water |

- All non-metallic. No nuts, bolts, washers or any other metal parts to corrode or degrade over time.

- Designed for carrier pipe diameters from 0.83 (21mm) to 37.60 (955mm) in diameter.

- Segmented pieces - small inventory may be used to accommodate a large variety of pipe styles, types and diameters. No extra trips from job site to warehouse for additional parts.

- Easy assembly. Simply slide the segments together and ratchet tight with patented Slide-Lock connecting system.

- Wide variety of runner heights to allow numerous options for pipe positioning within the casing.

- Runner variations may be used to adjust for grade.

- Manufactured from UV resistant polypropylene.

- High impact strength, 1.5 ft. lbs./inch (0.8 joules/cm).

- Excellent compressive strength, 3,000 psi (211 kg/square cm.).

- 800 volts/mil. dielectric strength.

- Wide temperature range;

- Eliminates sand or grout fill.

- No special tools required for installation.

- Low coefficient of friction for ease of installation.

- Will accommodate small conduit attachment for communications or electrical cable.

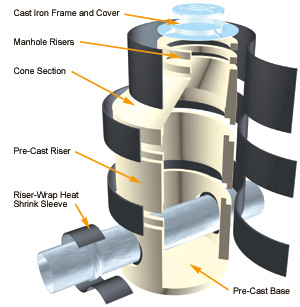

PSI / Pikotek Riser-Wrap® Sealing System

The Riser-Wrap seal is a two-layer

system designed for corrosion and sealing

protection on pipelines and encapsulating

manholes to seal joints against ground

water infiltration.

The first layer is a visco-elastic adhesive

liquid sealant covered by a heat shrink

sleeve. The heat shrink is a thick-walled

.098” (2.5mm),cross-linked, high density

polyethylene membrane.

protection on pipelines and encapsulating

manholes to seal joints against ground

water infiltration.

The first layer is a visco-elastic adhesive

liquid sealant covered by a heat shrink

sleeve. The heat shrink is a thick-walled

.098” (2.5mm),cross-linked, high density

polyethylene membrane.

Applications:

- Manhole Encapsulation/Sealing

- Pipelines

- Repair and Rehabilitation

- Step-Down Joints

- Square/Rectangular Vaults

- Septic Tanks/Vaults

Low Preheat Requirements

Preheat required only to remove the moisture

from the surface and for fast/easy installation.

Offers Permanent Heat Change Indicators

Permanent Heat Indicator ensures that the

correct application of heat has been applied

to the entire heat shrink sleeve.

Installation is fully inspectable at

any time after the installation.

High Modulus of Elasticity Backing

Accommodates ground movement.

High Impact and Penetration Resistance

Toughness to resist soil stress.

High Shrink Force

Optimizes flow and fill of visco-elastic

adhesive sealant.

Seals against ground water infiltration.

Impermeable

Provides corrosion protection.

Extends structure life.

No Special Tools

Quick & easy installation.

Sizing Calculation Program

On-line at www.riserwrap.com.